Engineering for performance

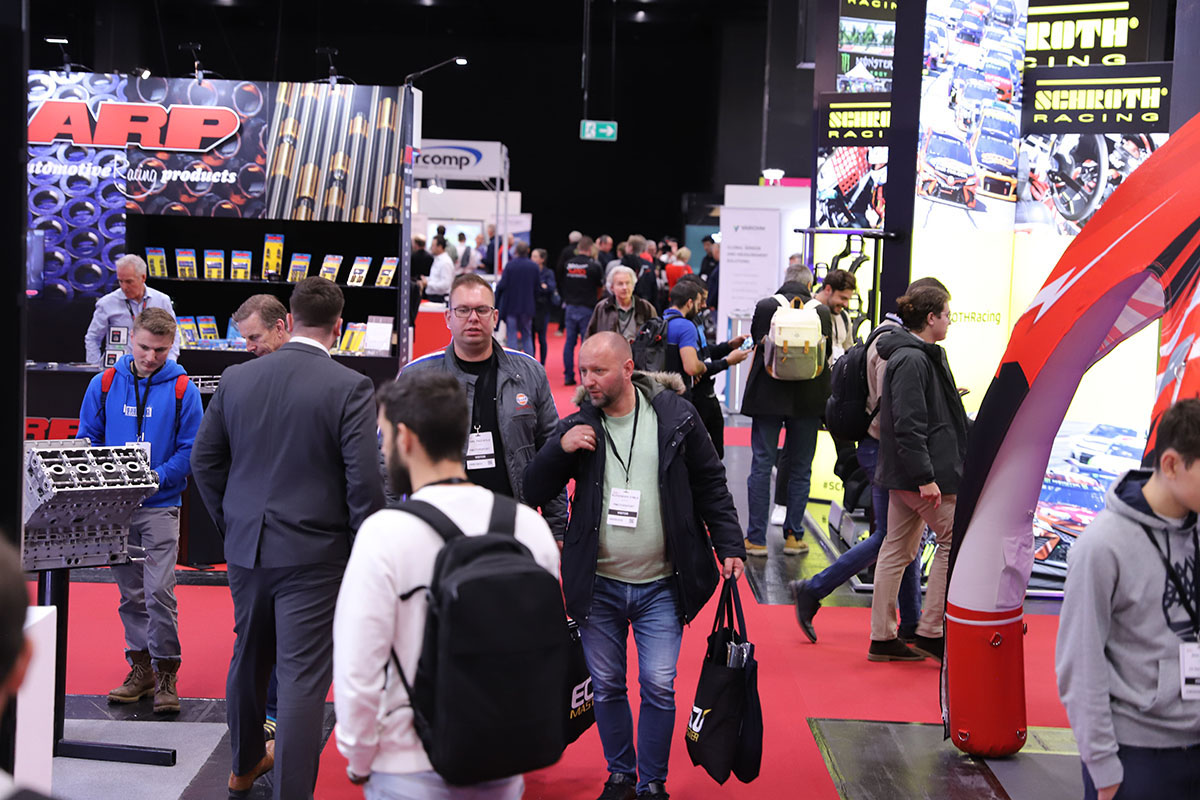

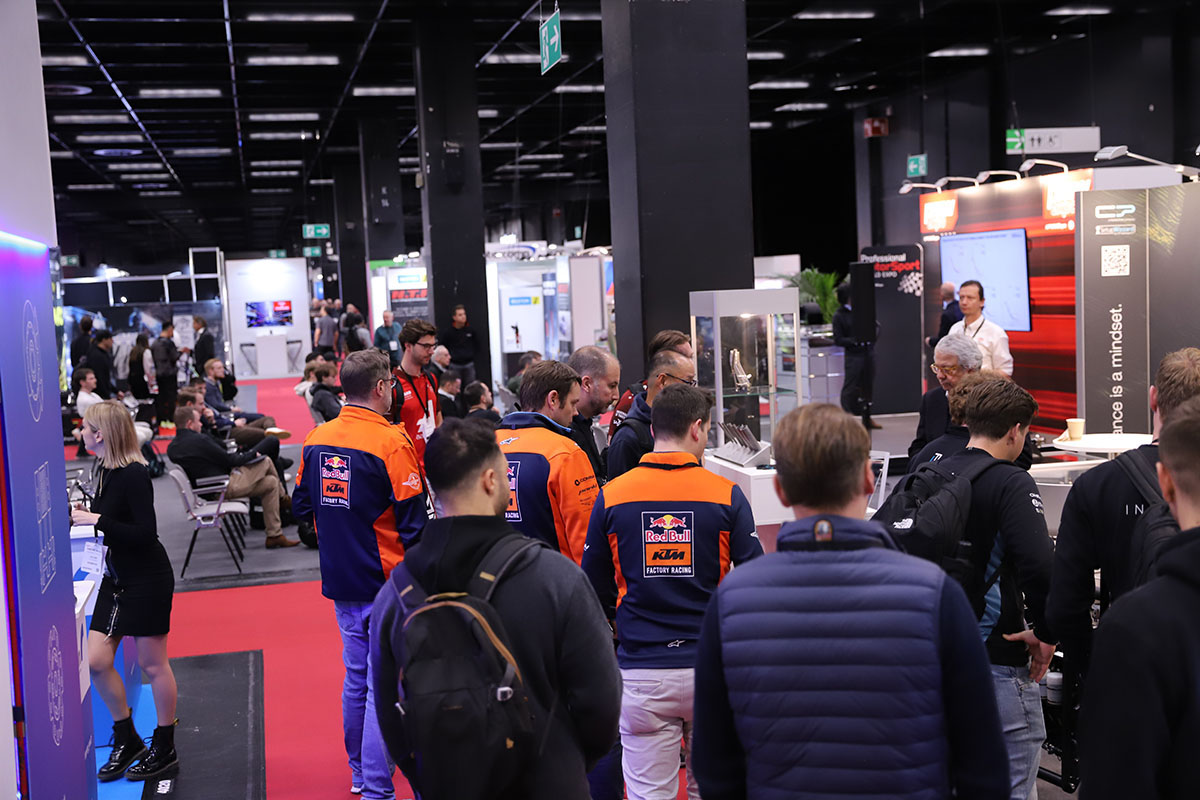

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW

Engineering for performance

THE MOTORSPORT AND PERFORMANCE AUTOMOTIVE ENGINEERING SHOW